If you rely on a ductless HVAC system to keep your home comfortable, neglecting regular maintenance could lead to bigger problems than you think. While ductless systems are celebrated for their energy efficiency, flexibility, and low-profile design, many homeowners mistakenly believe they are “set-it-and-forget-it” solutions. But does a ductless system need maintenance? The short answer is yes—and skipping it can cost you. In reality, even the most advanced systems require routine upkeep to perform at their best.

Without proper maintenance, small issues—like clogged filters, refrigerant leaks, or dirty coils—can snowball into major breakdowns, poor air quality, skyrocketing energy bills, and even costly system replacements.

In this blog, we’ll answer the key questions about what maintenance is needed for a ductless system, explain why it matters, and show you how to protect your investment for the long haul. Stay ahead of issues before they disrupt your home’s comfort.

Reasons Why Regular Maintenance Is Required for Ductless Systems

Optimizing Energy Efficiency

If the maintenance for the ductless system is neglected, the system’s efficiency can significantly decline. Dust and debris accumulate over time, causing the filters, coils, and blower to work harder to maintain desired temperatures. This overexertion results in increased energy consumption and, consequently, higher utility bills.

Preventing Expensive Repairs

Skipping periodic maintenance allows minor issues, like a slightly bent coil fin or an undercharged refrigerant line, to go unnoticed until they cascade into compressor failures or control board damage.

A simple filter swap or coil straightening (often under $100 in labor) can prevent a compressor replacement that averages $1,200–$2,500. By catching problems early, you can keep repair costs manageable, avoid unexpected breakdowns, and continue enjoying the benefits of a ductless mini-split AC.

Extending Lifespan

Much like automobiles, HVAC systems that receive regular tune-ups live longer. While typical ductless units last 12–15 years, routine cleanings and refrigerant checks can push that to 18 or even 20 years. Extending your system’s life by just 3–5 years delays the $5,000–$8,000 expense of a full replacement, providing a much stronger return on your original investment.

Enhancing Indoor Air Quality

A well-maintained ductless system guarantees proper airflow and filters out pollutants, allergens, and bacteria. Neglecting cleanings lets those contaminants recirculate, worsening asthma, allergy, and sinus issues. Regular filter changes and coil cleanings can reduce airborne particulate counts by up to 60%, helping vulnerable occupants breathe easier, reduce sick days, and even lower long-term healthcare costs.

Signs Your Ductless System Needs Maintenance

Reduced Cooling or Heating Efficiency

A healthy ductless unit typically shows a temperature split (ΔT) of 15–20 °F (8–11 °C) across the evaporator coil in cooling mode. A ΔT below 12°F often indicates problems such as coil fouling or low refrigerant charge. Additionally, dirty filters and coils cause an increase in airside static pressure (ΔP). When the pressure drop exceeds approximately 0.5 inches W.C. (125 Pa), the blower motor compensates by drawing more current, leading to a reduction in airflow (CFM) by more than 10%.

Unusual Noises

Rattling, grinding, buzzing, or high-pitched squealing noises during startup or operation often indicate mechanical issues. Loose fan blades or motor mounts can cause vibration peaks exceeding 0.005 inches peak-to-peak (pp), detectable with an accelerometer. Meanwhile, high-frequency hissing or whining sounds near service ports may signal refrigerant flow restrictions, typically caused by a partially blocked capillary tube or malfunctioning expansion valve.

Increased Energy Consumption

A noticeable spike in kWh usage compared to previous billing cycles under similar weather conditions often points to system inefficiencies. The Coefficient of Performance (COP) can drop from approximately 3.5 to below 2.5 when coils are fouled or the refrigerant charge is low, forcing the compressor to work around 40% harder to deliver the same BTU output. During inspections, technicians measure compressor amperage and compare it to the unit’s nameplate rating; amperage draws exceeding 110% of rated values typically indicate excessive head pressure caused by dirty condenser coils.

Foul Odors

After choosing the right ductless system for your home, it’s important to pay attention to any unusual smells. If you notice musty or burning smells while your system is running, it could indicate mold growth in the filters or ducts, or overheating components. The condensate pan and evaporator coil surfaces can harbor bacteria and mold, releasing volatile microbial organic compounds (mVOCs). A sharp, ozone-like or burning plastic odor may signal arcing at terminal connections or overheating capacitors. These issues can be detected using infrared thermal imaging, which identifies hot spots greater than 20°F above surrounding components.

Frequent On/Off Cycling

When a unit turns on and off rapidly, with cycles lasting less than 5–7 minutes and never reaching a steady state, it often indicates a problem with the system’s control or refrigerant levels. If the temperature swing is less than 1°F before the system shuts off, it could mean the control board is misreading sensor inputs or the refrigerant charge is incorrect. Low refrigerant levels can trigger a low-pressure cut-out within 2–3 minutes, while an overcharged system can trip a high-pressure cut-out, both leading to premature cycling and potentially damaging the compressor.

Visible Refrigerant or Oil Stains

Oily residue or frost patches around service valves, brazed joints, or coil fins are signs of potential refrigerant leaks. Using UV dye or halide detector probes can help identify micro-leaks, as even a 5% loss in refrigerant charge can reduce system capacity by about 10%. Additionally, compressor oil carry-over onto coils is an indicator of improper refrigerant charge (either too low or too high), which can impair heat transfer and reduce system efficiency if not addressed promptly.

Ductless doesn’t mean maintenance-free. Call now for a quick and thorough service.

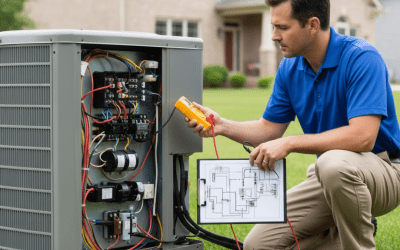

What Does Ductless System Maintenance Involve?

Cleaning or Replacing Filters

Technicians remove each indoor unit’s washable filter, inspect it under bright light, then either gently wash it with a mild, pH-neutral detergent (to avoid coating the mesh) or replace it with OEM spare filters. A clean filter should exhibit <100 Pa pressure drop at the system’s rated airflow. Dirty filters can double that drop, forcing the blower to draw extra amps and overheat.

Inspecting Coils

Both the indoor (evaporator) and outdoor (condenser) coils are examined for dust, grime, microbial growth, or oil stains (which indicate refrigerant/oil carry-over). A low-foam, no-rinse cleaner is applied, followed by gentle rinsing or brushing to restore full heat-exchange capacity.

Refrigerant System Evaluation

Leak-detection tools (electronic probes or UV dye) are used to identify any refrigerant loss at joints and service ports. Suction and discharge pressures are measured, with superheat/sub-cooling values compared against factory specifications to confirm correct charge.

Cleaning & Leveling the Outdoor Unit

Debris—leaves, grass clippings, and dirt—is cleared from around the condenser to ensure unobstructed airflow. The unit’s mounting is checked for levelness (to prevent oil pooling) and adjusted if the tilt exceeds acceptable limits.

Inspecting Electrical Connections

All terminal connections, relays, capacitors, and circuit boards are visually checked for signs of arcing, corrosion, or wear. Sensor resistances and control voltages are tested against expected values to ensure accurate operation.

System Startup & Performance Verification

At last, power is restored, and the indoor/outdoor units synchronize. Airflow volumes, temperature splits (Delta-T), and noise/vibration levels are recorded to confirm that the system meets manufacturer performance targets. Diagnostic logs are downloaded from the control board or remote interface to catch any intermittent faults.

How Often Should You Service a Ductless System?

How often does a ductless HVAC need maintenance? To answer this question, well, the specific frequency of maintenance depends on various factors, such as your system’s usage and the environment in which it operates. However, the general guideline is as follows:

DIY Upkeep (Every 4–6 Weeks)

- Air-Filter Cleaning: Remove and either rinse washable filters or replace disposable ones. In dusty or pet-friendly homes, you may need to clean them every 2–3 weeks instead.

- Visual Inspection: Give both indoor and outdoor units a quick once-over—wipe down the indoor unit’s exterior, clear leaves or debris from the outdoor condenser, and check that drain pans and condensate lines are unobstructed.

Full Professional Service (Once or Twice per Year)

- Standard Usage: Schedule a comprehensive service once annually.

- High-Usage or Commercial Environments: If your mini-split runs nearly year-round or services a dusty/industrial space, consider biannual professional visits (spring and fall) to stay ahead of wear and refrigerant drift.

Event-Triggered Service

After major storms, power surges, or long periods of inactivity, it’s wise to have a quick post-event inspection to catch bent fins, electrical shorts, or debris ingress before they become larger problems.

Expert Maintenance for Year-Round Efficiency!

A ductless system is a fantastic investment for any homeowner. However, like any home appliance, it requires time and care to maintain its performance. Be proactive about servicing your system periodically, and consider reaching out to the professionals at Classic Services Air Conditioning & Heating for an annual tune-up. Our certified technicians perform detailed inspections, clean filters and coils, check refrigerant levels, and test electrical components. With our proactive service plans for AC repair in New Braunfels, we help homeowners avoid costly repairs and enjoy year-round comfort.