Problems such as faulty wiring, loose connections, failing capacitors, or damaged circuits can interrupt the power supply that your AC relies on to operate efficiently. This not only increases energy consumption but also places stress on key components like the compressor, which can lead to costly repairs or even complete system failure.

The challenge is that electrical issues in AC systems often start small and go unnoticed. By the time the symptoms become obvious, performance has already dropped, and internal damage may have begun.

This guide breaks down the most common electrical faults that affect cooling efficiency, how they impact system performance, and why timely diagnosis and preventive maintenance are critical to keeping your AC running reliably and cost-effectively.

Key Electrical Components in AC Systems

Understanding the electrical parts of your system is essential because many of these are frequent AC repair components that directly affect cooling performance.

Compressor:

The heart of any AC system, the compressor, requires significant electrical power to pressurize refrigerant. It operates through a dedicated circuit and contactor, making it particularly vulnerable to electrical issues like voltage fluctuations and capacitor failures.

Capacitors:

These components store electrical energy to help motors start and run efficiently. Start capacitors provide the initial power surge needed to begin motor operation, while run capacitors maintain consistent voltage during operation.

Contactor and Relay Switches:

These electromagnetic switches control power flow to major components like the compressor and condenser fan motor. Contactors can wear out from repeated cycling, developing pitted or corroded contacts that impede proper electrical connection.

Thermostat:

The system’s control center, the thermostat, monitors temperature and signals the AC to cycle on or off. While often battery-powered, hardwired thermostats depend on proper electrical connections to communicate with the system.

Circuit Breakers and Fuses:

These safety devices protect the AC system from electrical overload. Frequent tripping indicates underlying issues that require investigation.

Condenser and Blower Fan Motors:

These motors circulate air through the condenser coils and the indoor air handler. They require stable power delivery and functional capacitors to operate efficiently.

Signs of Electrical Problems in AC Units

- Frequent Circuit Breaker Trips: If your AC repeatedly trips the breaker, it suggests electrical overload, short circuits, or ground faults. This should never be ignored, as it poses both efficiency and safety concerns.

- Unusual Sounds: Clicking, buzzing, or humming noises often indicate electrical problems. A clicking sound that doesn’t result in the unit starting suggests contactor issues. Continuous buzzing may point to loose wiring or failing capacitors.

- Inconsistent Cooling: If your AC struggles to maintain set temperatures or produces weak airflow, electrical issues affecting the compressor or fan motors could be the culprit. Voltage irregularities prevent these components from operating at full capacity.

- Burning Smells: Any burning odor near your AC unit demands immediate attention. This indicates overheating wires, failing components, or electrical shorts, all serious fire hazards.

- AC Won’t Turn On: Complete system failure often stems from electrical problems like blown fuses, tripped breakers, failed capacitors, or thermostat malfunctions.

Common Electrical Issues in AC Systems

Capacitor Failure

Capacitors have a limited lifespan and degrade from heat exposure, voltage fluctuations, and normal wear. When capacitors fail, motors struggle to start or maintain proper operation. A start capacitor failure prevents the compressor from initiating, while a run capacitor issues cause motors to overheat and operate inefficiently. This reduces cooling capacity while increasing energy draw.

Contactor Problems

Electrical arcing gradually damages contactor surfaces, creating resistance that prevents proper current flow. Worn contactors may weld shut (causing the AC to run continuously) or fail to close completely (preventing the system from starting). Either scenario compromises cooling efficiency and component longevity.

Wiring Issues

Corroded, loose, or damaged wiring disrupts electrical flow throughout the system. Oxidation builds up on connection points, creating resistance that generates heat and reduces power delivery. Rodent damage, environmental exposure, and age-related insulation breakdown all contribute to wiring problems that diminish system performance.

Thermostat Malfunctions

Faulty thermostats send incorrect signals to the AC system, causing short cycling (frequent on-off cycling) or preventing the unit from responding to temperature changes. Wiring issues between the thermostat and AC unit, dead batteries, or failed internal components all affect cooling efficiency by disrupting proper system operation.

Compressor Electrical Failures

The compressor draws substantial current and operates under considerable electrical stress. Challenging start problems, winding damage, or motor burnout can result from voltage irregularities, capacitor failures, or age-related degradation. A failing compressor dramatically reduces cooling capacity while consuming excessive energy.

Refrigerant Sensor Issues

While not purely electrical, the sensors monitoring refrigerant pressure and temperature rely on electrical circuits to communicate with system controls. Sensor failures can cause the system to operate outside optimal parameters, even when mechanical components function correctly, reducing efficiency.

Don’t risk DIY fixes! Let our licensed technicians handle diagnostics and repairs expertly.

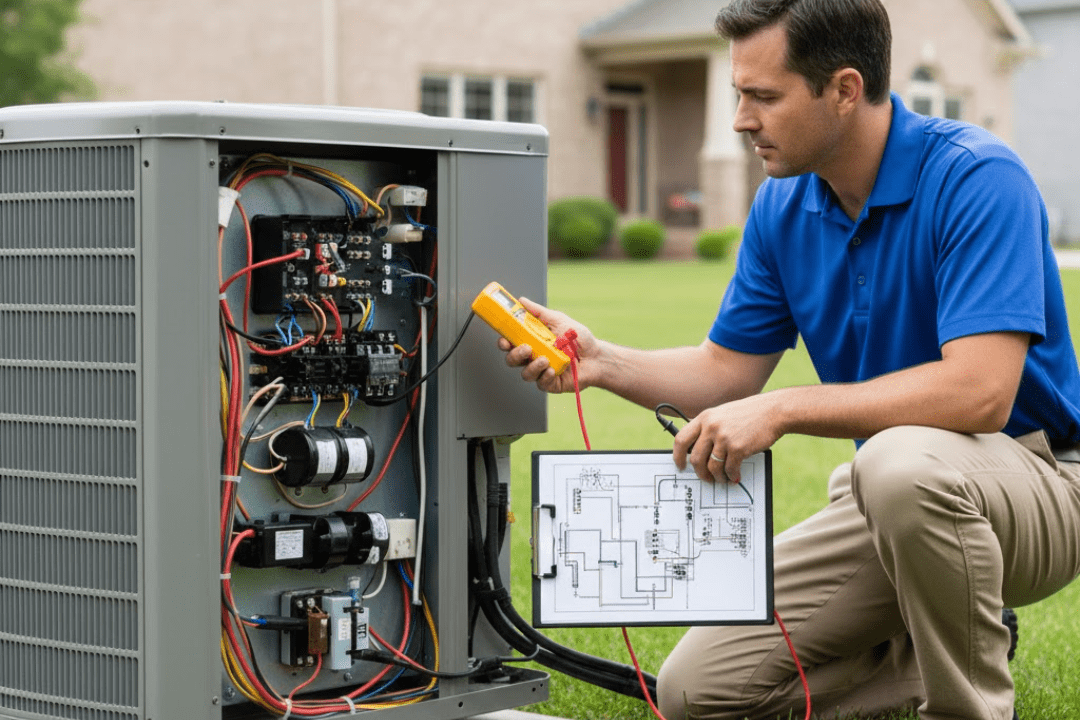

How Professionals Diagnose and Fix Electrical Issues Safely?

Initial Safety and Power Isolation

Before beginning diagnostic work on AC electrical issues, HVAC technicians always disconnect power to the AC unit to prevent electrical hazards. This crucial first step ensures the safe handling of high-voltage components such as compressors, capacitors, and contactors. Professionals follow lockout/tagout (LOTO) safety protocols to prevent accidental energization during inspections or repairs.

Detailed Visual and Component Inspection

A thorough visual inspection follows, where experts examine wiring, terminals, connectors, and insulation for signs of burning, corrosion, or loose joints. Damaged or oxidized wiring can cause voltage fluctuations, which can impact compressor efficiency and fan performance. Technicians also check for overheated contactors or misaligned relays, which often lead to erratic cooling cycles.

Electrical Testing with Precision Instruments

Professionals employ digital multimeters and clamp meters to measure voltage, current, and resistance across the system. Testing components such as capacitors, motors, and transformers helps identify irregular readings that indicate faults. For example, a weak capacitor may cause hard-starting compressors, while unbalanced voltage can lead to motor burnout.

Advanced Diagnostics for Modern Systems

In inverter-based or smart AC units, technicians use diagnostic software and manufacturer-specific tools to analyze electronic control boards and sensors. They interpret error codes, check sensor outputs, and evaluate the operation of variable-frequency drives (VFDs) or electronic expansion valves (EEVs) to pinpoint deeper AC electrical problems.

Safe Repairs and System Validation

After identifying the root cause, professionals may replace faulty capacitors or relays, repair burnt wiring, or tighten electrical connections to ensure optimal current flow. Post-repair, the system is retested to verify voltage balance and stable operation. This final validation step confirms that the AC system functions efficiently and safely within its designed electrical limits.

Preventive Tips to Avoid Electrical AC Problems

While you should always call professionals in the event of emergency electrical issues with AC, preventing such shortcomings is crucial to avoid costly repairs. Follow these suggestions for uninterrupted cooling:

- Schedule professional inspections twice a year to check wiring integrity, capacitor health, and voltage balance.

- Keep the condenser and air filters clean to prevent strain on electrical components.

- Ensure tight electrical connections and promptly replace frayed or corroded wires.

- Use a dedicated circuit and surge protector to safeguard against power fluctuations.

- Avoid overloading circuits with multiple appliances on the same line.

- Monitor unusual noises, burnt smells, or tripped breakers.

Conclusion

Consistent inspections, prompt repairs, and proactive maintenance are essential for preventing unexpected electrical issues in AC systems. And to do it efficiently, you need reliable HVAC experts. At Classic Services Air Conditioning and Heating, we combine technical expertise with advanced diagnostic tools to deliver precise, long-lasting solutions. For expert maintenance and reliable AC repair near Boerne or surrounding areas, count on our team to keep your premises comfortably cool year-round.