In Texas, the climate is unpredictable and relentless, with long stretches of 90–100°F summers, high humidity, to cold months, and systems running 2,500+ hours per year. HVAC equipment in Texas works harder and wears out faster than in most of the U.S. About 53% of home energy use goes to heating and cooling, making HVAC the largest electric load in many Texas homes. That’s why understanding when to repair, install, or replace your system becomes paramount.

In this guide, we break down what Texans need to know to keep cool, stay safe, and make smart HVAC decisions year-round.

Key Takeaways

- Understanding HVAC in the Texas Climate

- Professional HVAC Repair Services Across Texas

- HVAC System Replacement for Improved Efficiency & Performance

- Expert HVAC Installation Services

- Preventive HVAC Maintenance & Seasonal Tune-Ups

- Indoor Air Quality Solutions for Healthier Homes

- HVAC Cost Guides & Smart Decision Support

- How to Choose the Right HVAC Company in Texas

Understanding HVAC in the Texas Climate

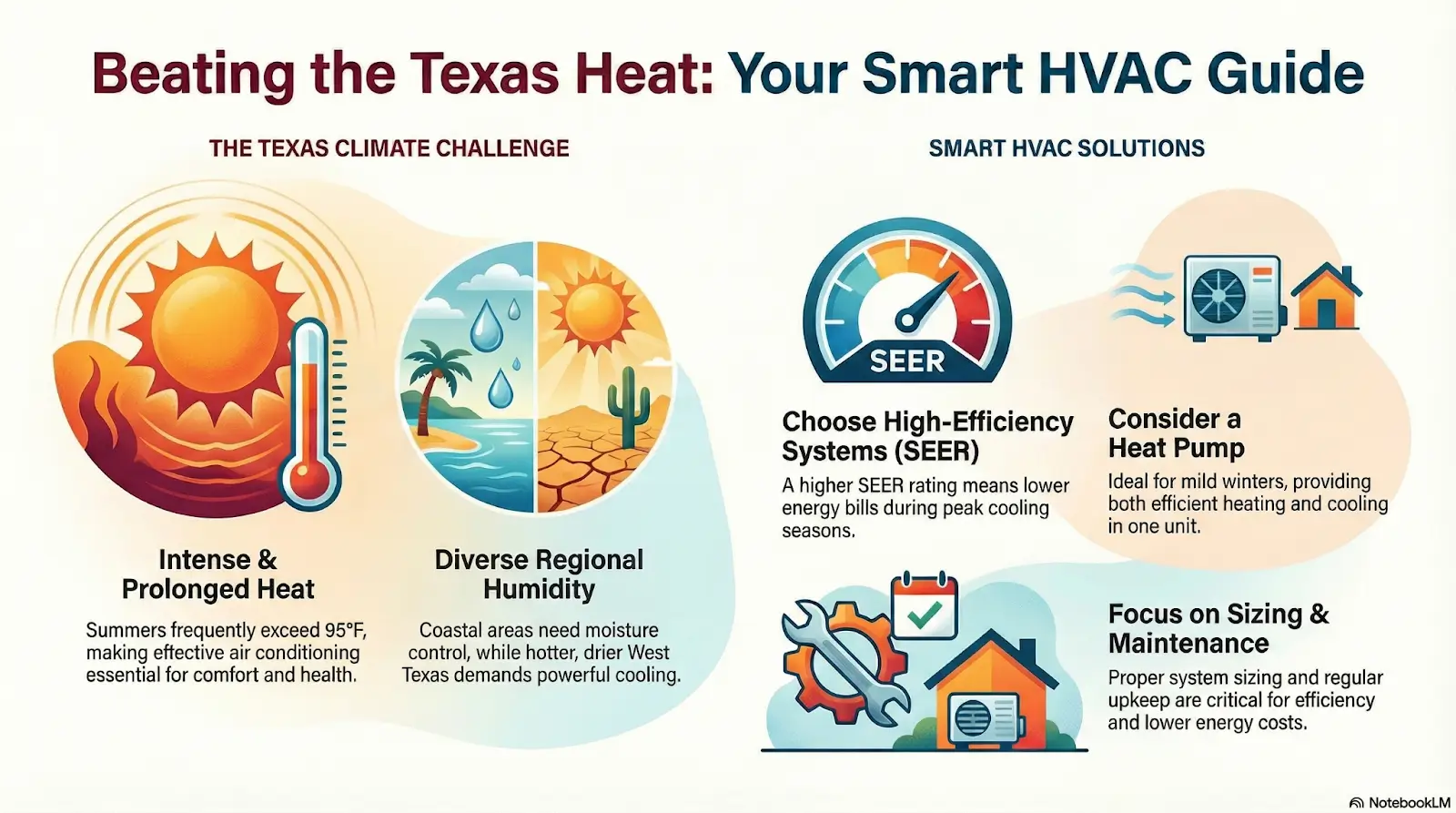

Understanding HVAC in the Texas climate requires recognizing the state’s extreme heat, regional humidity differences, and growing energy demands. Much of Texas experiences long, hot summers with temperatures frequently exceeding 95°F, making air conditioning essential for comfort and health. Eastern and coastal regions face high humidity, which requires HVAC systems with effective moisture control, while West Texas is hotter and drier, emphasizing efficient cooling capacity. Because cooling accounts for a significant portion of household energy use, high-efficiency systems rated by SEER (Seasonal Energy Efficiency Ratio) are especially important. Heat pumps are increasingly popular due to Texas’s relatively mild winters, providing both heating and cooling. Proper system sizing, insulation, and the importance of regular AC maintenance are critical to avoid breakdowns, improve efficiency, and reduce the risk of costly HVAC repair during peak summer months.

How HVAC Systems Work?

HVAC systems work by regulating indoor temperature, humidity, and air quality to maintain comfort and safety.

- Heating: Furnaces or heat pumps generate heat and distribute warm air through ducts or radiators during cold weather.

- Cooling: Air conditioners and heat pumps remove indoor heat using refrigerant, a compressor, and evaporator and condenser coils.

- Ventilation: Fresh outdoor air is brought in while stale air, moisture, and pollutants are expelled to maintain healthy airflow.

- Air Distribution: Ductwork or air handlers circulate conditioned air evenly throughout the building.

- Control System: Thermostats monitor temperature and signal the system to start or stop as needed.

- Air Filtration: Filters capture dust, allergens, and particles, improving indoor air quality and system efficiency.

Together, these components operate as a coordinated system to deliver consistent comfort, extend system lifespan, and help homeowners understand how you can get the best results from your HVAC system year-round.

HVAC Repair Services in Texas

Common HVAC Problems in Texas

Texas weather places heavy strain on HVAC equipment, leading to frequent service calls and premature wear of frequent AC repair components such as capacitors, contactors, and motors.

- Compressor Overload or Failure: Prolonged Texas summer heat forces compressors to run continuously, increasing the risk of overheating and mechanical failure.

- Capacitor Burnout: High outdoor temperatures shorten capacitor lifespan, a leading cause of sudden AC breakdowns in Texas.

- Duct Leakage and Heat Gain: Attic ductwork is exposed to extreme heat, causing energy loss and reduced cooling efficiency.

- Poor Humidity Control: Inadequate system design or aging equipment fails to remove moisture, especially in coastal and East Texas regions.

- Thermostat Malfunctions: Heat exposure and aging sensors can cause inaccurate temperature readings and improper system cycling.

- Evaporator Coil Corrosion: Humidity and airborne contaminants accelerate coil deterioration, reducing heat transfer efficiency.

- Condenser Coil Fouling: Dirt, grass, and debris restrict outdoor unit airflow, raising operating pressures.

- Short Cycling: Oversized units cool too quickly without dehumidifying, increasing wear and energy consumption.

- Refrigerant Line Insulation Damage: UV exposure degrades insulation, reducing cooling performance.

Signs You Need HVAC Repair in Texas

Ignoring early warning signs often leads to frequent AC repair components like the compressor failing, and higher costs.

- AC Runs Constantly Without Reaching Set Temperature

- AC keeps tripping the circuit breaker

- Hot or Cold Spots caused by airflow or duct issues

- High Indoor Humidity despite normal cooling operation

- Delayed Start-Up or System Hesitation

- Burning, Musty, or Chemical Odors from vents

- Frequent Breaker Trips indicating electrical strain

- Visible Ice or Water Leaks near indoor units

- Sudden Loss of Airflow from vents

- Excessive Outdoor Unit Noise or Vibration

Commercial and Residential HVAC repair

HVAC repair services differ between residential and commercial systems due to system size, complexity, and usage demands.

Residential HVAC Repair

Residential HVAC systems are designed for single-family homes, apartments, and small residential buildings. Repair services commonly include fixing air conditioners, heat pumps, furnaces, and ductless systems. Typical residential repairs address refrigerant leaks, airflow issues, thermostat malfunctions, electrical component failures, and worn motors or capacitors. Because residential systems experience frequent cycling during extreme heat or cold, timely repairs help prevent energy loss, indoor comfort issues, and unexpected breakdowns. Another question homeowners often ask is how long AC units lasts, and the answer typically ranges from 10–15 years, longer with proper care.

Commercial HVAC Repair

Commercial HVAC systems serve offices, retail spaces, warehouses, and industrial facilities and are larger and more complex. Repairs often involve rooftop units, packaged systems, variable refrigerant flow (VRF) systems, and advanced control systems. Commercial HVAC repair includes diagnosing airflow imbalances, control system failures, compressor issues, and ventilation problems. Due to higher occupancy and extended operating hours, commercial systems require rapid response, detailed diagnostics, and strict compliance with building codes and safety standards.

HVAC Repair Services in Texas

- Central AC Repair

Addresses refrigerant leaks, frozen coils, compressor failure, airflow issues, and electrical component damage caused by extended summer operation. - Ductless Mini-Split Repair

Involves fixing sensor errors, drainage clogs from humidity, inverter board failures, refrigerant issues, and indoor unit airflow problems. - Heat Pump Repair

Common services include repairing reversing valves, defrost cycle malfunctions, refrigerant leaks, and reduced heating or cooling efficiency during temperature extremes. - Furnace and Heating Repair

Includes ignitor replacement, blower motor repair, cracked heat exchanger inspections, flame sensor cleaning, gas valve issues, and thermostat faults. - Comprehensive System Diagnostics

Common electrical issues in ACs can arise at any time; hence, technicians test electrical components, airflow, refrigerant pressure, thermostats, and safety controls to identify hidden issues. - Refrigerant Leak Detection & Recharge

EPA-certified technicians locate leaks and restore proper refrigerant levels to maintain cooling efficiency. - Electrical Component Repair

Replacement of capacitors, contactors, relays, motors, and control boards stressed by high temperatures. - Ductwork Inspection & Sealing

Repairs air leaks, damaged insulation, and airflow imbalance common in attic duct systems exposed to extreme heat. - Drain Line Cleaning & Moisture Control

Prevents water backups, mold growth, and system shutdowns caused by Texas humidity. - Thermostat Repair & Smart Upgrades

Calibration, wiring repair, or installation of programmable and smart thermostats for improved efficiency. - Energy Efficiency Improvements

Airflow optimization, system calibration, and component upgrades to lower energy consumption and utility costs.

HVAC Replacement: Upgrade to Better Performance

While there are significant perks of routine HVAC repair, it is not always the most cost-effective or reliable solution. When systems become outdated, inefficient, or fail repeatedly, especially under Texas’s extreme heat, replacement offers improved performance.

Signs It’s Time to Replace Your HVAC

- System Age Exceeds 10–15 Years: Older systems lose efficiency and are more prone to breakdowns, and hence, the best solution is to get a new one.

- Frequent and Costly Repairs: Repeated repairs indicate declining reliability and rising ownership costs.

- Rising Energy Bills: Aging equipment consumes more energy to deliver less comfort.

- Inconsistent Cooling or Heating: Uneven temperatures suggest system capacity loss or design limitations.

- Uses Outdated Refrigerant (R-22): Phased-out refrigerants are costly and difficult to service.

HVAC Installation Services

A new HVAC installation should be considered for new construction, when upgrading systems older than 12–15 years, or if your current system has a history of frequent repairs, rising energy costs, or declining efficiency.

Choosing the Right HVAC System for Your Home or Business

- System Type Selection: Choose between central AC, heat pumps, ductless mini-splits, or packaged units based on building layout and climate needs.

- Central air systems are ideal for properties with existing ductwork and consistent cooling demands.

- Heat pumps provide both heating and cooling and are efficient in regions with mild winters.

- Ductless mini-splits are suitable for zoned comfort, room additions, or buildings without ductwork.

- Packaged units are commonly used in commercial buildings or homes with limited indoor space, as all components are housed in a single outdoor unit.

- Proper System Sizing: HVAC professionals perform Manual J load calculations that account for square footage, ceiling height, insulation levels, window type, orientation, occupancy, and local climate conditions. Proper sizing prevents short cycling, uneven temperatures, excess humidity, and unnecessary energy consumption while extending system lifespan.

- Energy Efficiency Ratings: Higher SEER, EER, and HSPF ratings reduce long-term energy costs.

- Climate Compatibility: Systems must be designed to handle prolonged heat and humidity.

- Ductwork Condition: Existing ducts must be sealed, insulated, or upgraded for optimal performance.

- Indoor Air Quality Features: Options include advanced filtration, humidity control, and ventilation upgrades.

The Installation Process Explained

Initial Consultation & Load Calculation

The process begins with a detailed evaluation of the property. Industry-standard load calculations (Manual J) are performed to accurately determine heating and cooling requirements.

System Selection & Design

Based on the load calculation results, technicians recommend HVAC equipment that meets capacity, efficiency (SEER, EER, HSPF), and layout needs. System design includes airflow planning, zoning considerations, and compatibility with existing infrastructure.

Removal of Old Equipment (if applicable)

Existing HVAC systems are safely disconnected and removed following local codes and EPA guidelines for refrigerant recovery and disposal.

Ductwork Inspection or Modification

Technicians inspect duct systems for leaks, insulation damage, and airflow restrictions. Repairs, sealing, resizing, or redesign may be performed to ensure balanced air distribution and minimal energy loss.

Equipment Installation

Indoor and outdoor units are properly positioned and secured. Electrical wiring, refrigerant lines, condensate drainage, and ventilation components are installed according to manufacturer specifications.

System Testing & Calibration

The system is tested for correct airflow, refrigerant charge, electrical performance, thermostat accuracy, and safety controls to ensure peak efficiency and reliability.

Final Inspection & Customer Walkthrough

A final inspection confirms code compliance and system performance. Homeowners or business owners are guided through system operation, maintenance requirements, and warranty details to ensure long-term satisfaction.

HVAC Maintenance & Tune-Ups

- Replace or Clean Air Filters Regularly: Dirty filters restrict airflow and reduce efficiency. Replace or clean filters every 1–3 months, depending on usage and indoor air quality needs.

- Schedule Professional Tune-Ups: Annual professional maintenance ensures proper system operation, identifies worn components early, and improves efficiency.

- Keep Outdoor Units Clear: Remove leaves, dirt, and debris from around condenser units to maintain proper airflow and prevent overheating.

- Check Thermostat Settings: Ensure thermostats are calibrated correctly and consider programmable or smart thermostats for better energy management.

- Inspect Ductwork for Leaks: Sealed and insulated ducts prevent energy loss and improve system performance.

- Clean Evaporator and Condenser Coils: Clean coils allow effective heat transfer and reduce system strain.

- Clear Condensate Drain Lines: Prevent clogs that can cause water damage and system shutdowns.

- Listen for Unusual Noises: Strange sounds often indicate loose or failing components requiring prompt attention.

Apart from this, homeowners often ask, does a ductless system need maintenance? Yes, ductless mini-splits also require regular filter cleaning, coil inspections, and drain maintenance to maintain efficiency and avoid performance loss.

How Often Should HVAC Maintenance Be Done?

In order to avoid costly HVAC repairs, here’s how often you should call in a professional for maintenance:

- Twice a Year (Recommended): Service cooling systems in spring and heating systems in fall to prepare for peak seasonal demand.

- Monthly or Quarterly: Check and replace air filters based on system use and household conditions.

- Annually: Have a full system inspection by a licensed HVAC professional to ensure efficiency, safety, and reliability.

- As Needed: Schedule inspections immediately if you notice reduced performance, unusual odors, or rising energy bills.

Indoor Air Quality Solutions

Apart from HVAC, another vital system that Texas homes and offices rely on is indoor air quality solutions. Here are a few things you should know about indoor air quality and it’s solutions:

Why Is Indoor Air Quality (IAQ) Important in Texas?

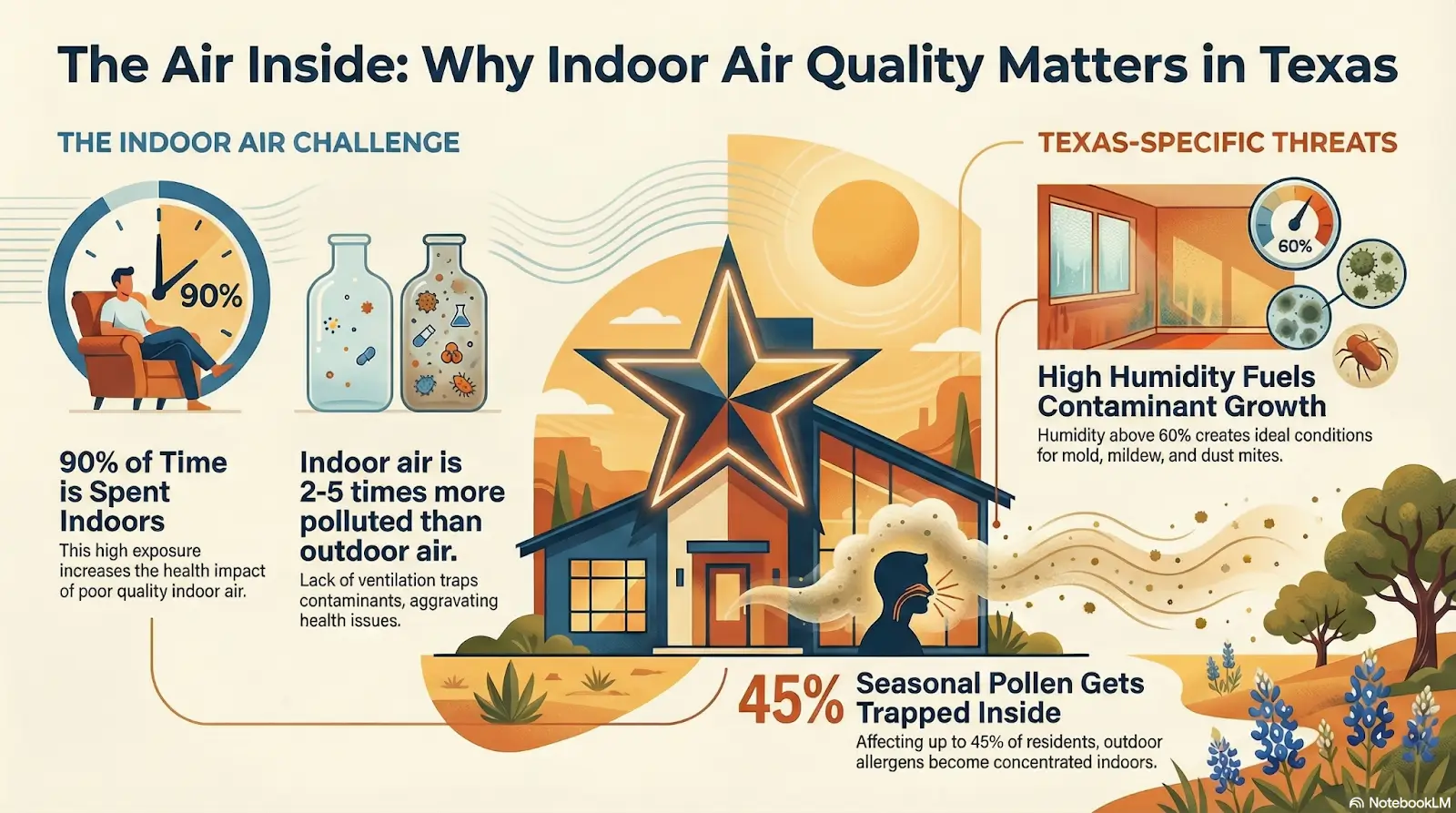

Indoor Air Quality (IAQ) is especially important in Texas because residents spend about 90% of their time indoors, where air can become 2–5 times more polluted than outdoor air, exacerbating health issues like allergies and asthma. Poor ventilation and the state’s high humidity levels create ideal conditions for mold, mildew, and dust mites to thrive, particularly in coastal and East Texas regions with humidity often above 60%, which fuels biological growth and airborne allergens. Seasonal pollen from ragweed and grasses—affecting up to 45% of residents in some areas- can infiltrate homes and become trapped, escalating respiratory irritation and allergic reactions. These indoor pollutants and irritants contribute significantly to asthma triggers and discomfort, making IAQ a critical component of health and comfort in Texas homes and businesses.

Indoor Air Quality Products

Filtration Systems

High-efficiency air filtration systems, including MERV-rated and HEPA filters, are designed to capture airborne contaminants such as dust, pollen, pet dander, and microscopic particles that standard filters often miss. They are integrated into the HVAC system to continuously clean air as it circulates, providing consistent air quality throughout the entire property rather than treating individual rooms.

Humidity Control

Humidity control systems, such as whole-home dehumidifiers, help maintain indoor humidity levels within the recommended 30–50% range. Proper moisture control prevents mold and mildew growth, limits dust mite populations, and improves overall comfort, especially in humid climates.

UV Lights & Air Scrubbers

UV germicidal lights are installed within HVAC systems to neutralize bacteria, viruses, and mold spores by disrupting their DNA, reducing microbial growth on coils and in ductwork. Air scrubbers actively remove airborne pollutants, odors, and volatile organic compounds (VOCs) through advanced purification technologies.

Cost Guides & Decision Help

HVAC Repair Cost Ranges

Residential HVAC repair costs in Texas vary widely based on the issue and system age. Basic repairs, such as capacitor or thermostat replacements, typically range from about $150 to $450, while more complex repairs, like blower motor fixes or refrigerant recharges, fall between $250 and $850. Larger component repairs (e.g., compressors or board replacements) can run up to $1,500 or more for major jobs. Seasonal peak demand often increases prices during the summer months because technicians are busier.

Installation and Replacement Estimates

The cost of HVAC installation or replacement in Texas varies based on system type, efficiency, and home size. Central AC replacements typically range from $6,000 to $14,000+, while complete heating and cooling systems average $7,000 to $15,000+. Heat pumps usually cost $4,500 to $8,500, ductless mini-splits range from $3,000 to $10,000+ per zone, and gas furnace installations fall between $2,500 and $6,000. Pricing is influenced by system capacity, efficiency ratings, ductwork condition, and local labor costs.

Choosing the Right HVAC Company in Texas

- Verify Licensing & Insurance: Ensure the company holds a valid Texas HVAC contractor license and carries liability and workers’ compensation insurance to protect your property and avoid liability.

- Check Experience & Local Reputation: Choose a provider with several years of local experience and positive word-of-mouth, as longer-standing companies understand Texas climate challenges (heat, humidity) and community needs.

- Read Reviews & References: Look at online reviews on Google, BBB, and Yelp, and ask for references to gauge service quality, reliability, and customer satisfaction.

- Evaluate Certifications & Technician Training: Technicians with industry certifications like NATE or EPA demonstrate professional expertise and adherence to technical standards.

- Request Detailed Written Estimates: Get itemized written quotes showing labor, parts, and warranties to compare pricing and avoid hidden fees.

- Compare Warranty & Maintenance Plans: Review manufacturer and workmanship warranties and check if they offer ongoing maintenance plans for long-term system care.

Conclusion

In a state where comfort is not optional, choosing the right HVAC partner is essential for peace of mind and performance. From expert guidance to dependable workmanship, Classic Services Air Conditioning & Heating stands out for its commitment to quality, integrity, and customer care. So reach out to our experienced team for reliable HVAC solutions that keep Texas homes and businesses comfortable year after year.

Our team is here to help you make confident, informed decisions, whether it’s service, repair, or an HVAC system upgrade.

FAQs

How often do HVAC systems fail during peak Texas summer heat, and what usually causes it?

HVAC failures peak during summer due to continuous operation, overheating compressors, electrical component failure, dirty coils, and inadequate maintenance.

Is it better to repair or replace an aging AC system in Texas’s hot conditions?

Replacement is better when systems exceed 10–15 years, face frequent repairs, have rising energy costs, or struggle during prolonged heat.

What size HVAC system is required for Texas homes with extreme summer temperatures?

Proper sizing depends on Manual J calculations, considering square footage, insulation, windows, occupancy, and regional heat intensity.

Why do air conditioners struggle to cool homes evenly in Texas?

Uneven cooling often results from duct leaks, poor insulation, improper sizing, zoning issues, or excessive attic heat gain.

How does Texas humidity affect HVAC performance and indoor comfort?

High humidity reduces cooling efficiency, increases run times, promotes mold growth, and makes indoor spaces feel warmer than actual temperatures.

What are the most common HVAC repairs needed in Central and South Texas?

Common repairs include capacitor replacement, refrigerant leaks, clogged drain lines, compressor strain, and airflow-related electrical issues.

When is the best time of year in Texas to install or replace an HVAC system?

Spring and fall are ideal due to milder temperatures, better scheduling availability, and potential cost savings.

How long should an HVAC system realistically last in the Texas climate?

Most HVAC systems last 10–15 years in Texas, depending on maintenance quality, usage intensity, and equipment efficiency.

What energy efficiency ratings actually matter for HVAC systems in Texas?

SEER, EER, and HSPF ratings matter most, as higher ratings reduce cooling costs during long Texas summers.

Are heat pumps a reliable option for both cooling and heating in Texas homes?

Yes, heat pumps perform efficiently in Texas due to mild winters and provide effective year-round heating and cooling.